Description

Classified according to IEC 61400-12-1 Edition 2.0 (2017-03)

The Thies FCA X Anemometer has the best classification values on the market.

Its built-in pressure sensor automatically corrects the wind speed measurement depending on air pressure.

The new low power version now has an even lower consumption (typ. 14 mA at 12 V) in IEC classified mode,

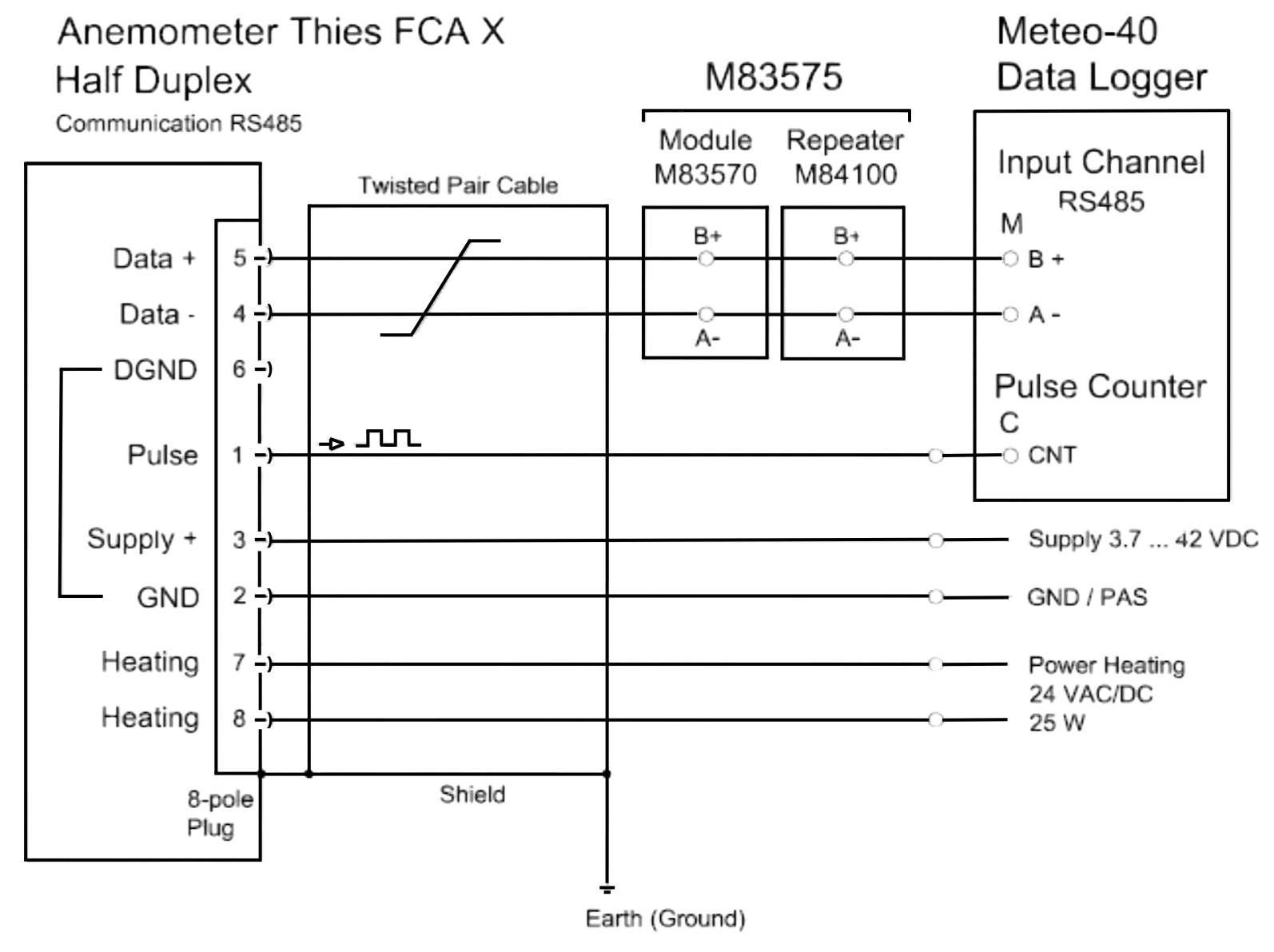

and up to eight sensors can be connected in a single bus.

Since the old version uses the same communication protocol as the new one, they can be used in the same bus.

Intelligent Optically-Scanned Cup Anemometer

Thies First Class Advanced X is classified acc. to IEC 61400-12-1 Ed. 2.0 (2017-03). It has been designed to

measure:

- Horizontal wind speed

- Absolute and relative air pressure

- Inclination X, Y and Z

- Acceleration, frequency and amplitude of vibration measurement in X, Y and Z

The anemometer is designed for wind resource assessment and power curve measurements.

It offers minimal deviation from cosine line, optimized dynamic behavior under turbulence,

low overspeeding, low starting threshold, and excellent oblique inflow behavior.

The ball-bearing cup star ensures low maintenance, and electronically regulated heating supports winter operation.

Intelligent Correction of Measurement Values

The sensor integrates automatic wind speed correction based on air pressure (700 … 1100 hPa).

Output includes both original and corrected measurement values.

Calibration

For wind resource assessments, anemometers must be MEASNET-calibrated.

Thies First Class Advanced X can store calibration slope and offset values internally.

Recommended calibration: Ammonit Wind Tunnel GmbH.

Configuration of Counter Output (IEC Classified Mode)

Parameter FO = 4: Counter output provides air pressure corrected wind speed for IEC classification.

Formula: wind speed [m/s] = 0.1 [m] × f [Hz]

Low Power Configuration (Heating OFF)

Default delivery: Low power configuration that also meets IEC classification.

Ideal for off-grid or limited-power scenarios.

Counter and serial outputs both provide air pressure corrected wind speed.

S Classification for Warm Climates

In regions where temperatures never drop below 10°C, the sensor in low power mode matches the IEC “Heating ON”

classification.

High Power Configuration (Heating ON)

For cold climates with sufficient power (up to 20W/sensor), request configuration for IEC mode with heating enabled.

Requires sensor version S11200H and special cable with heating cores.

Classification acc. to IEC 61400-12-1 Edition 2.0 (2017-03)

Air density effects were measured in a special wind tunnel setup (not via torque calculations).

| Class A* | Class B** | |

|---|---|---|

| Heating ON | 0.65 | 0.9 |

| Heating OFF | 1.1 | 1.8 |

Varel, Germany, 2017.

Operational Standard Uncertainty acc. to IEC 61400-12-1

Indicates max deviation at 10 m/s between real and measured wind speed:

| Class A* | Class B** | |

|---|---|---|

| Heating ON | 0.04 m/s | 0.05 m/s |

| Heating OFF | 0.06 m/s | 0.10 m/s |